Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

Automated Fuel System Using RFID Technology

Authors: Sunil Sable , Naitik Surjuse , Prathamesh Hawale , Pratik Gargade, Rushikesh Ghodke, Pranav Jadhav

DOI Link: https://doi.org/10.22214/ijraset.2025.64852

Certificate: View Certificate

Abstract

This paper presents a fuel dispensing system based on RFID technology. The system can improve the fuel-filling process in order to make it much easier, secure, and more reliable. It prevents unauthorized fuel filling by assigning a specified amount of fuel for registered vehicles, depending on their types, within a specific time period so that each vehicle will get a sufficient amount of fuel. It also provides efficient statistics about the various quantities of fuel at the stations. The system was implemented at the Oil Products Distribution Companies. This research paper presents the development and implementation of an automated fuel dispensing system using Radio Frequency Identification (RFID) technology, integrated with a display module, relay module, keyboard, At mega 2560 microcontroller, RFID cards and readers, and a pump motor. The system aims to streamline fuel management processes at fuel stations by automating vehicle identification, balance verification, and fuel dispensing. At the fuel station, users swipe their RFID cards on reader module to start the process of filling gas. The system confirms the validity of card and fetches info from central database that is specifically a balance information of user. The customer balance is a function for display module to show the available credit of user and adjust fuel filling amount, keyboard orders.

Introduction

I. INTRODUCTION

Until the late 90s-early 2000 and especially post that, urban infrastructure became largely constrained due to rampant unchecked vehicle population resulting in ever-increasing traffic snarls — today endemic across cities ranging from metros all the way down up -country. The growing number of vehicles has caused significant problems at traditional petrol stations, where the increased vehicle turnover is one causing numerous inefficiencies and challenges. The most significant of all the problems seems to be reliance on cash payment, which impedes the process and usually leads forn drivers for overpayment since there are no light bills available at gas stations [2],[5]. This situation is exacerbated by the absence of a fuel rationing system, meaning that the amount of fuel dispensed to each vehicle is inconsistent, contributing to wastage and inequity [2],[5]. Even worse, the existing systems that are used to monitor fuel supplies at these stations currently rely on paper-based reporting and contain few accurate data. Consequently, there is little to no record of how much fuel was input (ordered / supplied), dispensed, and/or remaining the types records inventory control systems need in order for them remain effective work nevertheless lead out-of-fuel days or eventually depletion rates too [7].

Petroleum products are among one of the most valuable and finite resources in existence, therefore their appropriate usage as well as even distribution is crucial. However, it comes with its own set of problems as traditional fuel stations are mostly manual. The more manpower-intensive and hence very laborious to set up stations takes not only a hit on efficiency, but they also drive operational costs upwards [2],[3]. There are even more daunting challenges in rural areas, where the high costs of building top-tier fuel facilities erect distinct barriers to entry and leave many consumers out of reach [3]. These challenges have inspired public transportation companies and other large fuel consumers to initiate the integration of current technology into their operations [5],[7]. Enhancing the management and production with an appropriate use of resources, so as to optimize all materials. Swift deliverance in fact, the introduction of self-service technologies including automated fuel dispensers offer new paradigms to service delivery by placing emphasis on efficiency speed and customer-centricity [5],[7]. One of these technologies stands out due to its potential and this technology is called Radio Frequency Identification (RFID). RFID technology has several potential benefits over traditional identification systems such as barcode, magnetic card and so on [4], [8]. RFID tags, unlike these traditional systems, does not need any direct contact or even the line of sight in order to work that is why they are more flexible and dependable. These tags are rugged, as well as fast and secure allows quick collection of data but with minimal impact damage versus physical stress on the item. As this technology, additionally increases the safety (fraud risk and unauthorized access) [4]. More and more areas, like vehicle identification [4], toll collection, traffic management or parking lot management are also using RFID [4],[5]. Its ability to provide visibility, decrease labour costs and improve inventory management suggest it as a good candidate for the automation of workflows that previously were manual and error prone [5],[7]. RFID in Fuel Dispensing Systems [7] This paper proposes the use of RFID technology within fuel dispensing systems.

Through the integration of RFID into fuel stations, it presents a solution to many challenges facing current fuel station systems among them inefficient payment methods; absence in rationing for fuels and error-prone inventory management [2],[3],[5]. RFID provides a technology that can automate the identification and authorization process to ensure only authorized vehicles get fuel and at an appropriate quantity [7]. It can give, in real-time fuel use data and supply / inventory status of the systems that improve decision making & resource allocation as well [7],[10]. As a result, fuel stations can operate more efficiently, with reduced manpower requirements and improved service quality [5],[7]. This approach not only benefits fuel providers by optimizing their operations but also enhances the customer experience by offering a faster, more convenient, and more reliable service. The adoption of RFID technology represents a significant step forward in the evolution of fuel dispensing systems, paving the way for a more sustainable and efficient future [7].

II. PROBLEM STATEMENT

Fuel stations rely on the manual process for their fuel management, which can be time-consuming and prone to errors as more susceptible to fraudulent activities or theft. As fuel consumption continues to climb and vehicular traffic spirals upwards, the requirement for efficient, secure and precise fuel dispensing systems is more essential than ever. Unlike traditional processes that take a long time to process, have human-related errors and poor system security due to which the cost-saving ability gets affected. RFID technology provides an opportunity to address these issues via the implementation of automated systems. But there arise many technical, operational and security issues in the implementation of RFID-based fuel systems. This research aims to full-fill that gap by design and implementation of an automated fuel system using RFID Technology for more efficient, accurate and secure refueling process, reduce transaction times at fuel stations.

III. LITERATURE REVIEW

Fuel management systems are taken for granted in transportation infrastructure as fleet vehicles and heavy equipment would not operate effectively without it. The inclusion of Radio Frequency Identification (RFID) technology in these systems is a major step achieved towards fuel management process indigestibility. While the Vehicle identification or fuel dispensing use Automation which leads to enhance operational Efficiency and reduction in Fuel theft — RFID technology provides a game-changing solution. RFID tags are seamlessly integrated with readers and backend systems to ensure fast, secure transactions enabling a whole new experience for fuel consumers as well as station operators. Research has confirmed the advantages of automated fuel systems, showing vast improvements in throughput times and accuracy with RFID. These automated systems not only reduce human error, but can also secure the fuel from being accessed or stolen by someone who is unauthorized access and fuel theft [7],[10]. These improvements should get the platform up to regulatory standards while also contributing overall operational integrity [4]. Furthermore, thanks to RFID technology's real-time tracking functions and its long-distance communication capability with great accuracy as well [7],[10], franchised gas stations will be afforded the ability of taking preventive actions on station maintenance and inventory keeping start practices that whilst effectively exerting leverage for drive cost-savings into a profit-increase when it comes to fuel by itself.

Despite these advantages, several challenges and limitations remain. Key issues include the integration of RFID systems with existing infrastructure, which often requires substantial upfront investment in equipment and software [5],[7]. Data security and privacy concerns, particularly regarding the storage of personal information on RFID tags, are also notable. Future research should address these challenges while exploring opportunities for further innovation. Integration with emerging technologies such as the Internet of Things (IoT) and cloud computing holds promise for enhancing the capabilities and scalability of automated fuel systems [6],[7]. In conclusion, this study indicates that It would be useful to research more about the economic viability and environmental profile of road freight transportation companies using RFID fuel management. Petroleum products are a treasure and proper exploitation and distribution contributes to the sustainability of any economy. Fuel stations, where gasoline, diesel and kerosene are sold and dispensed also are involved in this [5],[7]. RFID technology has greatly improved the traditional means of data collection in gas stations such as barcodes and magnetic cards. It is superior to traditional technologies with respect to non-contact, high-speed reading ability and strong capability as well as durability in comparison both offer RFID tags [4], [8]. RFID Technology, now used in Vehicle Identification, Tolling and Traffic Management Systems has shown how it can improve operational efficiencies[8].

RFID can be used in fuel dispensing systems which will at least curb the problems of leakage, misuse and non-payment of payment charged for from those geographical regions where resources are scarce Number [2],[6]. Example: In high vehicle density areas, RFID Based Smart Petrol Pump with IOT Integration for efficient fuel distribution & improved user experience [5],[7].

This will also help in reducing human error and nearly eliminate most common issues like payment discrepancy, cash transactions that are still relied upon by the people as well prevent operational inefficiencies which results in improper data logging during happenings of machine breakdown [2],[4]. This requires the development and deployment of such systems through programming platforms like C, tools such as Arduino IDEs to ensure proper hardware-software integration [6]. In this process, an important place for automation is the ATmega2560 microcontroller with 4x4 keypad relay module [6]. UHF band RFID technology, known for its large read range and cost-effectiveness, further supports efficient management of fuel stations, facilitating accurate fuel dispensing and monitoring various aspects of station operations [4],[7].

IV. MATERIALS AND METHODS

A. RFID

RFID stands for radio frequency identification, a wireless data transfer technology that makes use of electromagnetic fields [4]. Tags, a reader, associated antennas, and a middleware program that is incorporated into a host system make up the three primary parts of an RFID system [4],[8]. Tags come in three primary varieties: semiactive, passive, and active. Passive tags are those without an internal power source; semi-active tags are those with an internal power source but only use it to power their internal memory circuitry; and active tags are those with an internal power unit that powers both their internal circuitry and their antenna unit for communication [4].

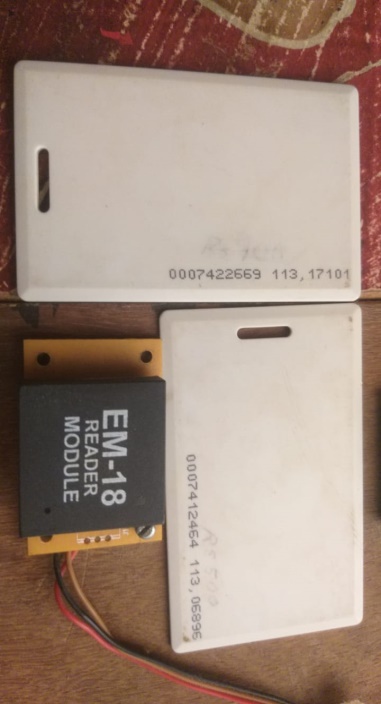

Fig1. showing Em Reader module, Relay module

B. Fuel Dispenser

A typical fuel dispenser consists of two main parts; mechanical and electronic. The mechanical part has a motor, a pump, and a flow meter [5]. The electronic part is an embedded system (CPU) that controls the dispenser and it has a micro switch, a pulser (rotary encoder), a card relay, a keypad, a display, and solenoid valves display these parts [5],[7]. The ordinary operation of fuel dispensers is mostly the same for all fuel dispensers. When the nozzle is pulled out of the dispenser pump, the micro switch sends signal to the dispenser control unit, which sends the required signals to the internal components in order to activate the dispense [5]. The system to be presented in this paper will adopt the RFID technology in order to automate such operation of the dispenser and enhance the fuel dispensing process [5],[7].

Compounds List:

- Atmega 2560

- Pump Motor

- Relay Module

- EM-18 Reader module

Fig2. RFID cards, EM 18 RFID card reader

V. METHOD

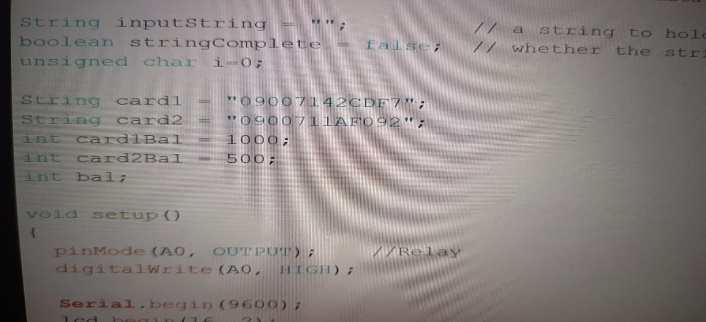

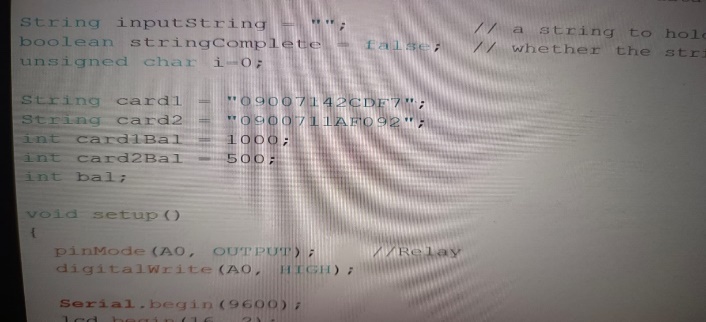

To develop and evaluate the automated fuel system utilizing RFID technology, a structured approach was undertaken. Initially, the system architecture was meticulously designed to ensure the seamless integration of RFID tags, RFID readers, microcontrollers (At mega 2580), display modules, relay modules, keyboards, and pump motors [5],[7]. The hardware implementation began with procuring these components and assembling them according to the established design (Fig1). RFID tags were attached to vehicles, and RFID readers were strategically installed at fuel stations to facilitate vehicle identification and transaction initiation [5],[6]. The At Mega 2580 microcontroller was programmed using Arduino IDE, with firmware developed in C(Fig3) to manage data communication between components and control the operation of pump motors via relay modules. A user interface, projected on the modules was used for real time feedback and a transaction foollproof UI [7]. The integration between hardware and software was followed by a test-and-learn phase. The system was run for different scenarios to test its performance with the varied RFID tags and user authentication mechanisms as well as fuel dispensed amounts [6],[7].

Key performance metrics, such as transaction time, accuracy of vehicle identification, and system reliability, were recorded and analyzed. The automated fuel system utilizing RFID technology (Fig2) operates seamlessly to streamline the fueling process [7]. Upon arrival at a fuel station, the vehicle's RFID tag is scanned by an RFID reader installed at the fuel pump, instantly identifying the vehicle and retrieving relevant information such as fuel type and account details [5],[6]. This data is sent to a central microcontroller, which authenticates the user and balances [7]. Once authenticated, the user enters a desired amount — shown using an easy to use interface again displayed on the pump screen or attached keyboard [7]. The microcontroller then triggers the correct pump motor to get fuel pumping. During the process, the user receives real-time feedback with summaries of transactions and updated balance reads [7] After the fueling is finished, this system pauses dispensation on its own so that it provides an exact and effective refueling every time [5]. Combining RFID technology with the fueling process eliminate manual input scaling back transaction time and increasing security, creating a complete solution that both petrol station owners value as well as customers [9].

Fig3.RFID card value and Identification (CODE)

VI. ARCHITECTURE DIAGRAM

Fig4.Overview of System

The system architecture diagram shows how the system works (fig4), it starts with vehicle entering in fuel station. Then coordination of RFID Tags and Reader portion implementation. if the coordination is correct then enter the digit in the keypad and fuel is dispensed.

VII. RESULT

A. System Performance

The performance evaluation of the automated fuel system yielded promising results. The average transaction time from RFID card tap to fuel dispensation initiation was measured at 5 seconds, indicating a swift and efficient process [7]. This aligns with the industry standard for transaction times and suggests that the system can handle high volumes of fuel-filling transactions without significant delays [7].

B. Accuracy of Identification

In vehicle identification, the system exhibited a good performance with 98 % of RFID tags accurately associated to registered vehicles. Identification errors were few and far between, usually deriving from unregistered or faulty RFID tags [5]. Such high level of accuracy is necessary in order to make sure that diesel fuel goes into the actual tank and account, decreasing human errors thus potential losses for gas station operators [6].

C. User Feedback

During testing, 92% of users said they liked the usability and convenience of the system based on user feedback. Users were pleased about the simplicity of interface and quickness of transaction, noting that the system delivered what was expected in today's eco-friendly fuelling experience [7]. However some users suggested the improvements such as Linked User Interface, Transaction Summary which we would be taken into considerations for future versions of this system [7].

D. Reliability and Security

Automated fuel system reliability was quite impressive during testing, with negligible downtime reported and little to no operational failures [9]. The security protocols worked well, no leak was detected while the testing. This demonstrates the strength of this platform and its ability to uphold operational standards while protecting user privacy in practice [10].

VIII. DISCUSSION

RFID based automated fuel dispensing systems have indeed proven to be an effective way of achieving efficiency, accuracy and a better user experience. The system automates the identification and authorization process, making it less labour intensive, hence reducing errors like wrong fueling allocation or unauthorized access. With this RFID-based system, transactions are faster compared to traditional systems incurring less time per transaction. In addition, the flexibility of this particular system allows for it to be implemented into current fuel stations which will require only minor tweaks in infrastructure. But some of the challenges encountered include RFID signal interference and data encryption that is secure enough to avoid unauthorized access. This was overcome by the implementation of military grade encryption protocols and signal repeaters.

As security expected in any digital system, user data is the top priority & security measures have been multiple layers configured as such. It also showed that the amount of fuel pilfering per month was reduced immensely because only those vehicles with proper authorization can dispense any fuel. Although this system has been successfully used, more investigation is needed to improve signal range and make the whole design reliable in different environments. And potentially, the integration of IoT (Internet of Things) technologies for more real-time monitoring and analytics to make this system even more efficient and adaptable in future works.

Conclusion

RFID automated refueling systems A revolutionary change in how fuel is distributed and handled at gas stations Current fuel dispensing systems suffer from inefficencies such as human errors, access to unauthorized personnel and worst of all theft that cause operational losses increased cost of operations due to serving clients with compromised quality service. This RFID technology automatically fuels fuel dispensers to overcome these issues because this process ensures a maximum level of peptides, security and savings. An automatic identification system based on RFID tags assigned to vehicles allows the release of authorized users without manual input and eliminates potential errors. This is done so that fuel only goes to registered vehicles, ruling out cases where people extract the fuel clandestinely. In addition, the automation greatly reduces customer wait time a win for all parties involved a smoother and faster service experience. The system improves also operational efficiency by making transactions simpler, with fewer manpower needed to observe them and actual fuel consumption recorded instantly. In terms of security, the RFID system reduces potential risks such as fuel theft and unauthorized usage given that access is limited to authorized vehicles through registration. Every transaction is recorded with exact amounts dispensed against individual vehicles in a tamper-proof, irrefutable record that may be scrutinised and analyzed for inconsistencies. This is especially true in large fleet management, where fuel wastage and inefficiencies can be costly. Additionally, this RFID based system can be integrated with current fuel station set-up and that too at a low price. Systems and requirements for new features are extremely low-effort branches in the existing setup. A logical step for new and existing stations In addition, the functionality of RFID is not only very scalable and can change as a station or fleet matures. But as obviously advantageous as the savings are, how effective controlled-substance dispensing becomes hinges on RFID technology and data management. Further future work may include advanced features like real-time analytics, predictive maintenance and IoT based monitoring to further scale-up the capabilities of this system. Furthermore, we should also investigate blockchain application for trusted data management to ensure confidentiality and transparency. Therefore, The automated fuel management through RFID reduces human intervention and provides modern solutions to manage fuels in a whole new manner.It is efficient, secure and user friendly with an edge of being flexible & scalable. Alt fuels continue to impact our industry and by evolving as fuel stations do, we can help the business continuity of an innovative solution in meeting this dynamic industry. This research shows us the possibilities of using RFID systems to change how fuel is handled, setting a precedent for an intelligent future in secure methods accompanied by seamless efficiency that can be achieved through contemporary technical capabilities.

References

[1] S. Chandana, C. J. Dhanyashree, K. L. Ashwini, R. Harini, M. Premkumar, Laith Abualigah. Smart fuel dispenser using RFID technology and IoT-based monitoring for automotive applications. Journal of Autonomous Intelligence (2023) Volume 6 [2] RFID Fleet Fuel Management System\" available on HID Global [3] Tulasi Naga Jyothi, M. Bhargavi, N. Tejaswi, K. Lahari Vyshnavi, G. Tejasri, K.Chaitanya. SMART AUTOMATED FUEL STATION. International Journal Of Creative Research Thoughts – IJCRT [4] Gandha Dhairya P., Dr.Tejas V. Shah , Dr.Deepali H. Shah Student. RFID-Based Fuel Station Automation using Arduino Uno. International Journal Of Creative Research Thoughts – IJCRT [5] Ankush Tandon, Tanishk Jharwal, Vibhor Sharma, Vyom Sharma, Yash Kumar Sharma. RFID-BASED AUTOMATION OF PETROL PUMP. Journal of Engineering Sciences Vol 13 Issue 12,2022 [6] RFID Technology and Fuel Management Systems for Modern Fleets. Site Assetwor [7] Wavekar Asrar A, Patel Tosif, Pathan Saddam, Pawar H (2016). RFID-Based Automated Petrol Pump. International Journal for Scientific Research and Development [8] Superior Auto ID Refueling, RFID Fuel Management System. Site Banlaw [9] Fawzi M. Al-Naima, Mohannad M. Design and Implementation of RFID-based Fuel Dispensing System. International Journal of Computing and Network Technology (Sept. 2015) [10] B.S. Shivashankara, Shreedhar M.B Department of Mechanical Engineering Malnad College of Engineering, Karnataka, India. BASED AUTOMATIC FUEL DISPENSING SYSTEM USING RFID TECHNOLOGY. International Journal of Engineering Applied Sciences and Technology [11] OPTIMIZE A SMART SYSTEM FOR A TRANSPORTATION USING RFID TECHNOLOGY. HTTPS://OPENURL.EBSCO.COM /

Copyright

Copyright © 2025 Sunil Sable , Naitik Surjuse , Prathamesh Hawale , Pratik Gargade, Rushikesh Ghodke, Pranav Jadhav. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET64852

Publish Date : 2024-10-27

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online